High-torque motor without using permanent magnets

High-torque motors with the circuit of the winding Slavyanka without using permanent magnets.

High-torque motors with the circuit of the winding Slavyanka without the use of permanent magnets has a unique ratio of power consumption. They are designed to operate in conditions of frequent, severe, prolonged start-UPS, large (over 10%) drops of the supply voltage. The vast majority of cases, high-torque motors solve the problem of engine starting without the use of frequency regulators.

To buy the product

Description:

The asynchronous motor winding of the type “spring” without the use of permanent magnets has a unique ratio of power consumption.

The scheme of the winding Slavyanka is a technology for creating low-noise high-torque energy efficient asynchronous motors.

High-torque motors with the circuit of the winding Slavyanka in its mounting dimensions fully meet the standard asynchronous electric motors, but, at the customer’s request, can be supplied in the version with reduced dimensions.

Such torque motors are designed to operate in conditions of frequent, severe, prolonged start-UPS, large (over 10%) drops of the supply voltage.

The vast majority of cases, high-torque motors solve the problem of engine starting without the use of frequency regulators. When working in conjunction with the frequency controller they provide mechanical properties unattainable for other series motors. When working with a frequently changing load, when working with nenominalnoe load, when changes in supply voltage the motors reduce energy consumption by 50%.

Advantages:

– have the ability to operate in the mode S1, and in operation S3,

– improved vibration-noise performance, the average sound level is below 5 dB,

– have a high reliability service factor of 2.5,

– higher starting torque of 35%,

– lower inrush currents by 35%,

– higher minimum torque of 35%,

– more maximum torque by 20%

– Efficiency and cos close to the nominal load range of 25 to 150%,

– a “soft” mechanical characteristics,

– large overload capacity,

– reduce power consumption by 50% when working with a frequently changing load, when working with nenominalnoe load, when changes in the supply voltage.

Comparative characteristics:

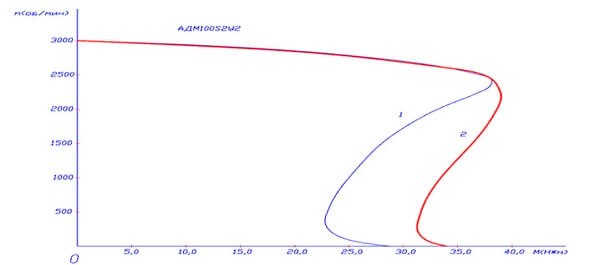

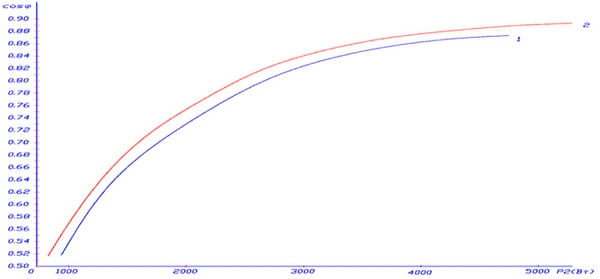

Sravnitelnyi General and the characteristics of torque motors with the circuit of the winding Slavyanka presented below.

1 – General (with standard coil)

2 – high-torque (with the scheme of the winding Slavyanka)

Mechanical characteristics:

Graph of power factor:

Schedule efficiency:

Application:

– transport system

– lifting equipment,

– fans,

– pumps,

– compressors,

– gearboxes

– machines, etc.

High-torque motors are advantageous to use in any field, replacing their regular three-phase asynchronous motors.

Specifications:

Power: from 0.18 to 11 kW.

Supply voltage: any up to 1000 V.

Motors suitable for operation in climatic performances: U2, U1, UHL2, NF1, T2, T1 according to GOST 15150.

Nominal values of climatic factors of the environment according to GOST 15543.1 (p. 2; 5,14) and GOST 15150 (p. 1,4), wherein:

– height above sea level 1,200 m,

– dustiness of air no more than 1.3 g/m3

– the environment is not explosive, does not contain conductive dust, vapors do not contain substances harmful influence on insulation.

Degree of motor protection: IP 55 or IP54 according to GOST 17494.

The motors can be equipped with integrated thermal protection.

Group mechanical effects for resistance to external mechanical influencing factors GOST 17516.1 М3по (p. 13; 6; 15).

Method of cooling IC0141 according to GOST 20459 (p. 6).

Insulation oil-resistant insulation class F (155оС) or H (180 ° C) according to GOST 8865 (p. 15).

Operation mode: continuous S1 and intermittent duty S3 according to GOST 183. Intermittent operation mode PV from 0 % to 50 %. Allowed to work with PV from 50% to 100 % within two hours, but not more often than once in 3 hours of operation. The average number of starts of the electric motor of not more than 30 per hour. Number of starts per day is not more than 200. The total number of launches during the year are not more than 30,000.

The engines are at operating temperature, allowed to stand for 2 min without visible damage and residual deformations, the speed increase to 120% of nominal.

The engines withstand the Parking lot under short-circuit current after the steady-state nominal operation at a nominal voltage not less than 10 s.

Insulation of the stator winding relative to the housing and between the windings can withstand for 1 minute test voltage 2500 V 50 Hz.

Insulation of the stator winding between the adjacent turns of her stand idle for 5 minutes test voltage above the nominal values by 50% with increased supply frequency by 20%.

Engines withstand 50% overload current for 2 minutes.

Engines, starting from a height of rotation 80, have provisions for lifting and transportation.

The motors have a terminal box with two Salnikova inputs, allowing the ability to rotate 180º with the aim route cables from both sides.

The method of protection from electrical shock motors are class 1 according to GOST 12.2.007.0. In terms of fire safety the engines meet the requirements of GOST 12.1.004. The risk of fire does not exceed 10-6 per year.