Chromium diamond composite coating

Chromium diamond composite coating.

Chromium diamond composite coating belongs to the category metalloorganic coatings. It has improved characteristics and properties (high hardness, wear resistance, corrosion resistance, low coefficient of friction, etc.), several times or several dozen times greater than the properties of a simple metal chrome coating.

Feature chrome-diamond composite coatings

Properties and benefits of chromium diamond composite coating

The application of the chromium diamond composite coating

Feature chrome-diamond composite coatings:

Chromium diamond composite coating belongs to the category metalloorganic coatings. It has improved characteristics and properties (high hardness, wear resistance, corrosion resistance, low coefficient of friction, etc.), several times or several dozen times greater than the properties of a simple metal chrome coating. It contains dispersed particles of nanodiamonds.

As a result, the coating increases the abrasion resistance:

| moulds for cold pressing of metal powders | 10 times |

| tool for cold drawing of metals | 2.5 times |

| cutting tools | 1.5-15 times |

| the cutting tool to the fiberglass | 4-10 times |

| knives for cutting papers | 4-5 times |

| needle files | up to 10 times |

| saw blade paintings | 4-6 times |

| tool for osteoporosi, dental burs | in the 8-11 times |

| dies, knives for meat grinders | 3-6 times |

| moving parts of looms, spinning and winding machines | 8-10 times |

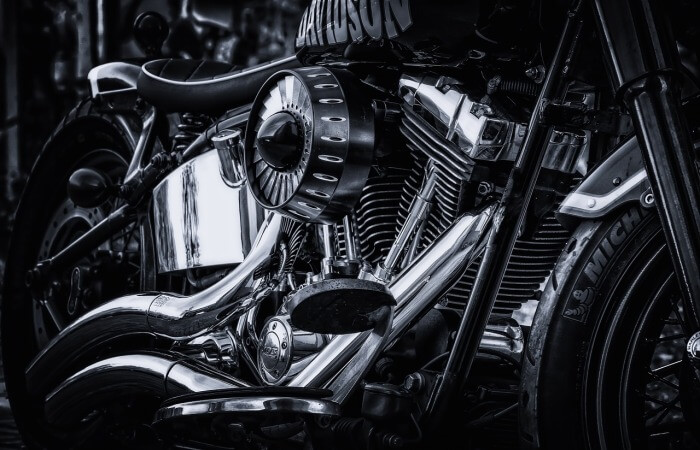

Chrome-diamond coatings have good appearance – silvery gray with a bluish or milky opaque hue.

Properties and benefits of chromium diamond composite coating:

– improves surface hardness and wear resistance of parts, good resistance to uniformly distributed load,

– durability nanodiamond chromium plating in comparison with hard chrome plating increases 2 – 5 times,

– coefficient of friction of nanodiamond chromium plating in comparison with hard chrome plating is reduced by 15-25 %,

– chrome-diamond composite nano-coating due to their more non-porous structure has a higher corrosion resistance,

– has a high chemical stability in the atmosphere of sulfur compounds in the solutions of organic and inorganic acids in a tropical climate,

– has a heat resistance and a tendency to passivation in air,

– two or more times increases the service life of parts and components, working in conditions of abrasive and corrosive wear

– all cutting tool, there is a significant reduction of the cutting force, reduce material buildup on cutting surfaces.

– increasing of durability of details of machines and mechanisms, resource tool, saving high speed steels and hard alloys, electricity and labour.

The use of chrome-diamond composite coatings:

Coatings based on chromium and nanodiamonds are used for hardening of cutting, pressing, stamping, drilling, medical and other tools, parts of machines and mechanisms, various tooling.

Note: © Photo ,