The technology of concreting under extreme pressure “Eco-concrete”

The technology of concreting under extreme pressure “Eco-concrete”.

The technology of concreting under extreme pressure “Eco-concrete” is a revolutionary new technology aimed at creating concrete structures of high density with improved physical and mechanical properties. Technology “Eco-concrete” eliminates the use of traditional methods of concreting, special expensive formwork and vibrating machines. “Eco-concrete” as the technological process of compaction of concrete mix is based and is directed to the use of physical properties, mass, inertia themselves of solid particles of the concrete mix (gravel, sand and cement).

Schematic diagram of the technology of concreting under extreme pressure

Description:

The technology of concreting under extreme pressure “Eco-concrete” is a revolutionary new technology aimed at creating concrete structures of high density with improved physical and mechanical properties. Technology “Eco-concrete” eliminates the use of traditional methods of concreting, special expensive formwork and vibrating machines.

“Eco-concrete” as the technological process of compaction of concrete mix is based and is directed to the use of physical properties, mass, inertia themselves of solid particles of the concrete mix (gravel, sand and cement).

The technology of concreting under extreme pressure “Eco-concrete” covers the process of preparing a concrete mixture in a sealed chamber of high-speed mixer, its transport under ultra-high pressure (1.4 MPa with a speed of 120-200 m/s) and concreting in water-aerosol medium in a hermetically sealed system that eliminates dust pollution and rebounds.

This requires a specially-designed mechanized complex, which provides the implementation of these technological processes: preparation of the concrete mixture in a sealed chamber high-speed mixer, carrying it under extreme pressure through the sleeve to the place of concrete and concreting in water-aerosol medium in a hermetically sealed system that eliminates dust pollution and rebounds, a special end device, and a nozzle.

In this case, high density concrete and reinforced concrete structures is achieved by the seal and displace water and air from the concrete mix in the peripheral surface of concrete.

The technology of concreting under extreme pressure “Eco-concrete” provides strength to the homogeneous single layer of concrete mix in the early stages of concreting up to 40%.

The technology of concreting under extreme pressure “Eco-concrete” provides carrying out of works on reconstruction of buildings, structures, objects without stopping the technological process, and no evictions.

“Eco-concrete” high-density, deposited under ultra-high pressure, has high performance properties including high resistance to abrasion and a higher resistance to weathering and atmospheric agents.

When construction and repair works of hydraulic structures (dams, hydropower plants, sewage treatment plants, reservoirs, retaining walls of channels large and small rivers, etc.) this technology allows you to recover without stopping.

Recovery engineering, water supply, Sewerage and stormwater networks can be produced from the inside, without exposing the plumbing (and other networks) and not making excavations.

Advantages:

– high economic efficiency. The technology eliminates the use of formwork and vibrating machines

– eliminates the use of traditional methods of concreting,

– high ecological cleanliness of workplaces and the environment, a sudden decrease in dust content and process bounces from 30% to 2%,

– significant reduction of construction costs,

– increase performance of concrete and concreting 10 times

– the increase of Flexural strength, compressive strength, modulus of elasticity of the structures by 20% or more,

– elimination of the shrinkage of the concrete mix,

– increases the safety of production operations due to higher grasp the concrete in its early stages and gaining strength

– reduce labor costs, consumption of materials and timing of construction (reconstruction),

– high resistance to surface abrasion and its higher resistance to weathering and weathering,

– the strength of a homogeneous single layer of concrete mix in the early stages of concreting up to 40%,

– conducting of works on reconstruction of buildings, structures and objects without stopping the technological process, and no evictions.

Schematic diagram of the technology of concreting under extreme pressure:

1 – high density concrete with strength up to 40%,

2 – pushed out of the concrete, water and air.

Application:

– civil and industrial construction, including:

– construction and reconstruction of hydraulic structures, dams, hydropower plants, sewage treatment plants, reservoirs, retaining walls of channels large and small rivers,

– strengthening of buildings and structures in areas of natural disasters from earthquakes, landslides and subsidence of the soil, floods and the effects of military operations,

– waterproofing of underground buildings and structures from the penetration of groundwater

– the protection and promotion of the mines in the mines after production to ensure ecological purity and stability of the environment

– restoration of objects of metallurgical production, smelting, blast furnaces and other heating units without stopping the production

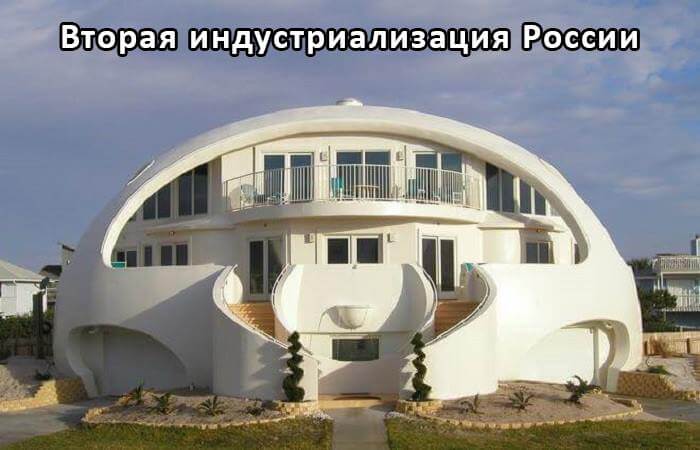

– construction and erection of new fantastic objects lunar and space architecture by using computer graphics and inflatable air-supported formwork, reinforced or fibroareolar structures, and the subsequent dismantling of the air-supported formwork for re-use

– operated the construction of roofing systems.

Note: the description of technology on the example of the technology of concreting under extreme pressure “Eco-concrete”.