Laser marking

Laser marking.

Laser marking is the impact of laser radiation on the material, which changes its surface and forms a high-quality image high definition.

The advantages of laser marking

Description:

Nowadays, almost any manufactured goods must be accompanied by a marking. It may contain information about the manufacturer, date of manufacture, serial number etc. Without this information it is impossible to ensure due process of the production of goods and the receipt of its sale. Today laser marking is the most modern and technologically advanced method of marking products.

The principle of laser marking is the influence of laser radiation on the object material, in which there is a change in the surface of marked material, which allows to obtain high-quality image high definition on the material of the product. Change of optical, chemical or geometric properties of the marked material is due to its local heating, melting and partial evaporation.

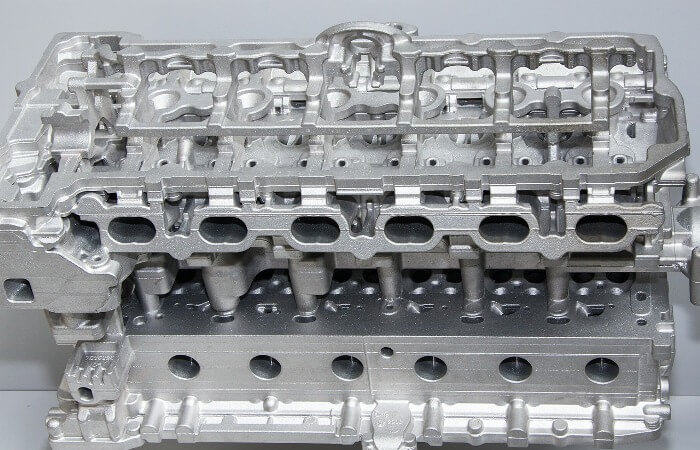

Laser marking is subjected to almost all types of materials:

– metals, including hard alloys,

– painted, varnished, coated with a chemical method of surface

– various plastics: polycarbonate, polystyrene, polyamide, ABS,etc.,

– ceramic (boron nitride, silicon, aluminum , etc.)

– special self-adhesive film,

paper, cardboard,

– other materials.

With laser marking you can apply the information on mass produced products, the serial products with quickly changing information, products with high demands on durability labelling, barcodes, etc. of the product.

The advantages of laser marking:

– if laser labelling is no mechanical effect on the material

– thermal effect of laser radiation is minimal,

– high resistance caused by the image to any effects on the material

– high speed and performance,

– possibility of marking in hard to reach places

– precision accuracy,

– high contrast,

– universal method of applying information

– durability,

– high efficiency at low operating costs

ease of operation even with non-standard surfaces,

– noncontact and no special requirements for the preparation of the product.

Note: © Photo ,