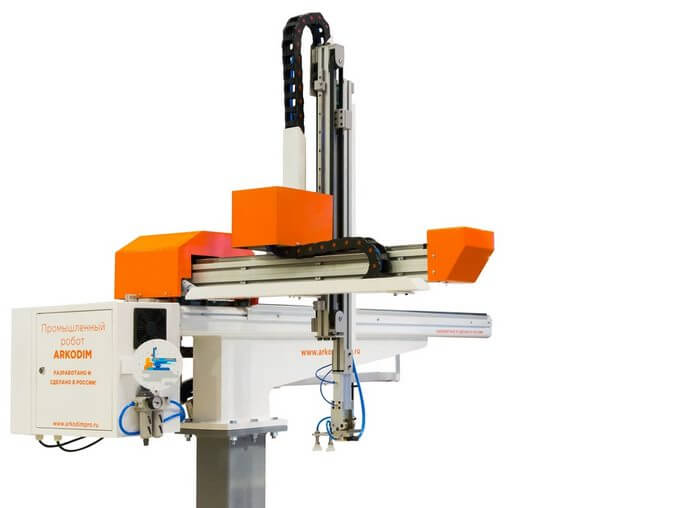

Industrial robot manipulators 3-7 axial

3-7 axis industrial robot manipulators ARKODIM for loading and unloading of workpieces, parts and their mistango transportation.

Industrial robot manipulators are used for service milling, turning and grinding CNC machine tools, casting equipment, stamping and forging presses, machining centers, etc. Under maintenance refers to the loading and unloading of workpieces, parts and their maintenacne transportation. Also, while the machines perform their basic functions, the robot can produce secondary operations: marking, trimming, blowing, etc.

Description:

Robots ARKODIM is 3-7 axis industrial robot manipulators cantilever type linear architecture.

Industrial robots ARKODIM are used for service milling, turning and grinding CNC machine tools, casting equipment, stamping and forging presses, machining centers , etc. Under maintenance of machine tools refers to the loading and unloading of workpieces, parts and their maintenacne transportation. Also, while the machines perform their basic functions, the robot can produce secondary operations: marking, trimming, blowing, etc. Industrial robots ARKODIM may as well be robots-welders, robot painters, robot palletizers, etc.

Industrial robots ARKODIM are made individually based on the customer’s specifications. Industrial robots can have different sizes, have different class of accuracy (accuracy of the robot ARKODIM to 0.1 mm), different speed, different capacity and have 3, 4, 5, 6 or 7 axes of motion.

Advantages:

– the robot design ARKODIM is a long-term operation without frequent maintenance

– they do not require complex maintenance and easily configured to perform different operations

– control of robots by a special program,

– industrial robots ARKODIM can be used with full integration of their own management system to the control system of the CNC machine. This minimizes the exchange of information between robot and machine, which significantly reduces the total duration of the production cycle.

Application:

The use of robotics in manufacturing leads to:

– high utilization of the machines;

– stability cycles;

– minimum reject ratio;

– the absence of accidents on manufacture;

– exception the “human factor”;

– save on the frame;

– to direct economic benefit.

Note: the description of technology for example, industrial robots ARKODIM.